Mold Remediation

Mold is detectable by smell and signs of water damage on walls or ceiling, and can grow in places invisible to the human eye. It may be found behind wallpaper or paneling, on the inside of ceiling tiles, the back of drywall, or the underside of carpets or carpet padding. Piping in walls may also be a source of mold, since they may leak (causing moisture and condensation).[8]

Spores need three things to grow into mold:

- Nutrients: Cellulose (the cell wall of green plants) is a common food for indoor spores.

- Moisture: To begin the decaying process caused by mold

- Time: Mold growth begins from 24 hours to 10 days after the provision of growing conditions.

Mold colonies can grow inside buildings, and the chief hazard is the inhalation of mycotoxins. After a flood or major leak, mycotoxin levels are higher even after a building has dried out.[7]

Food sources for mold in buildings include cellulose-based materials such as wood, cardboard and the paper facing on drywall and organic matter such as soap, fabrics and dust-containing skin cells. If a house has mold, the moisture may originate in the basement or crawl space, a leaking roof or a leak in plumbing pipes. Insufficient ventilation may accelerate moisture buildup. Visible mold colonies may form where ventilation is poorest and on perimeter walls (because they are nearest the dew point).

If there are mold problems in a house only during certain times of the year, the house is probably too airtight or too drafty. Mold problems occur in airtight homes more frequently in the warmer months (when humidity is high inside the house, and moisture is trapped), and occur in drafty homes more frequently in the colder months (when warm air escapes from the living area and condenses). If a house is artificially humidified during the winter, this can create conditions favorable to mold. Moving air may prevent mold from growing, since it has the same desiccating effect as low humidity. Molds grow best in warm temperatures, 77 to 86 °F (25 to 30 °C), although growth may occur between 32 and 95 °F (0 and 35 °C).[9]

Removing one of the three requirements for mold reduces (or eliminates) new mold growth:

- Moisture

- Food for the mold spores (for example, dust or dander)

- Warmth; mold generally does not grow in cold environments.

HVAC systems can produce all three requirements for mold growth. The air conditioning system creates a difference in temperature, encouraging condensation. The high rate of dusty air movement through an HVAC system may furnish ample food for mold. Since the air-conditioning system is not always running, warm conditions are the final component for mold growth.

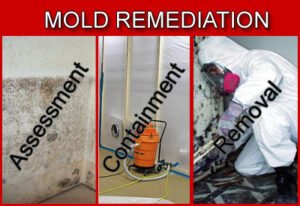

Assessment

The first step in assessment is to non-intrusively determine if mold is present by visually examining the premises; visible mold helps determine the level of remediation necessary. If mold is actively growing and visibly confirmed, sampling for its specific species is unnecessary.[8]

Intrusive observation is sometimes needed to assess the mold level. This includes moving furniture, lifting (or removing) carpets, checking behind wallpaper or paneling, checking ventilation ductwork and exposing wall cavities. Detailed visual inspection and the recognition of moldy odors should be used to find problems. Efforts should focus on areas where there are signs of liquid moisture or water vapor (humidity), or where moisture problems are suspected.

Sampling

The United States Environmental Protection Agency (EPA) does not generally recommend sampling unless an occupant of the space has symptoms. Sampling should be performed by a trained professional with specific experience in mold-sampling protocols, sampling methods and the interpretation of findings. It should be done only to make a particular determination, such as airborne spore concentration or identifying a particular species. Before sampling, a subsequent course of action should be determined.

In the U.S., sampling and analysis should follow the recommendations of the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), the EPA and the American Industrial Hygiene Association (AIHA).

Types of samples include:

- Air: The most common form of sampling to assess mold levels. Indoor and outdoor air are sampled, and their mold-spore levels compared. Air sampling often identifies hidden mold.

- Surface: Measures the number of mold spores deposited on indoor surfaces, collected on tape or in dust

- Bulk: Removal of material from the contaminated area to identify and quantify the mold in the sample

Multiple types of sampling are recommended by the AIHA, since each has limitations; for example, air samples will not identify a hidden mold source and a tape sample cannot determine the level of contamination in the air.

Remediation

The first step in solving an indoor mold problem is to remove the moisture source;[11] new mold will begin to grow on moist, porous surfaces within 24 to 48 hours. There are a number of ways to prevent mold growth. Some cleaning companies specialize in fabric restoration, removing mold (and mold spores) from clothing to eliminate odor and prevent further damage to garments.

The effective way to clean mold is to use detergent solutions which physically remove mold. Many commercially available detergents marketed for mold cleanup include an EPA-approved antifungal agent.

Significant mold growth may require professional mold remediation to remove the affected building materials and eradicate the source of excess moisture. In extreme cases of mold growth in buildings, it may be more cost-effective to condemn the building than to reduce mold to safe levels.

The goals of remediation are to remove (or clean) contaminated materials, preventing fungi (and fungi-contaminated dust) from entering an occupied (or non-contaminated) area while protecting workers performing the abatement.

Cleanup and removal methods

The purpose of cleanup is to eliminate mold and remove contaminated materials. Killing mold with a biocide is insufficient, since chemicals and proteins causing reactions in humans remain in dead mold. The following methods are used:

- Evaluation: Before remediation, the area is assessed to ensure safety, clean up the entire moldy area, and properly approach the mold. The EPA provides the following instructions:[8]

- HVAC cleaning: Should be done by a trained professional.[14]

- Protective clothing: Includes a half- or full-face respirator mask. Goggles with a half-face respirator mask prevent mold spores from reaching the mucous membranes of the eyes. Disposable hazmat coveralls are available to keep out particles down to one micrometer, and protective suits keep mold spores from entering skin cuts. Gloves are made of rubber, nitrile, polyurethane, or neoprene.

- Dry brushing or agitation device: Wire brushing or sanding is used when microbial growth can be seen on solid wood surfaces such as framing or underlayment (the subfloor).

- Dry-ice blasting: Removes mold from wood and cement; however, this process may spray mold and its bi-products into surrounding air.

- Wet vacuum: Wet vacuuming is used on wet materials, and this method is one of those approved by the EPA.[citation needed]

- Damp wipe: Removal of mold from non-porous surfaces by wiping or scrubbing with water and a detergent and drying quickly

- HEPA (high-efficiency particulate air) vacuum: Used in remediation areas after materials have been dried and contaminated materials removed; collected debris and dust is stored to prevent debris release.

- Debris disposal: Sealed in the remediation area, debris is usually discarded with ordinary construction waste.

Address:

32432 Dequindre Rd, Warren, MI, 48092

Email:

service@expertsolutionsmi.com

Service Hours:

24/7 Emergency Services 586-569-6168